Leather is such a fascinating material. Since the dawn of time, mankind has been using leather for a variety of applications. In this article you will find more about it’s production process, the different leather grades, and how the process of sourcing works at Bespoke Factory. (Estimated reading time: 3 minutes)

Leather Grades Explained

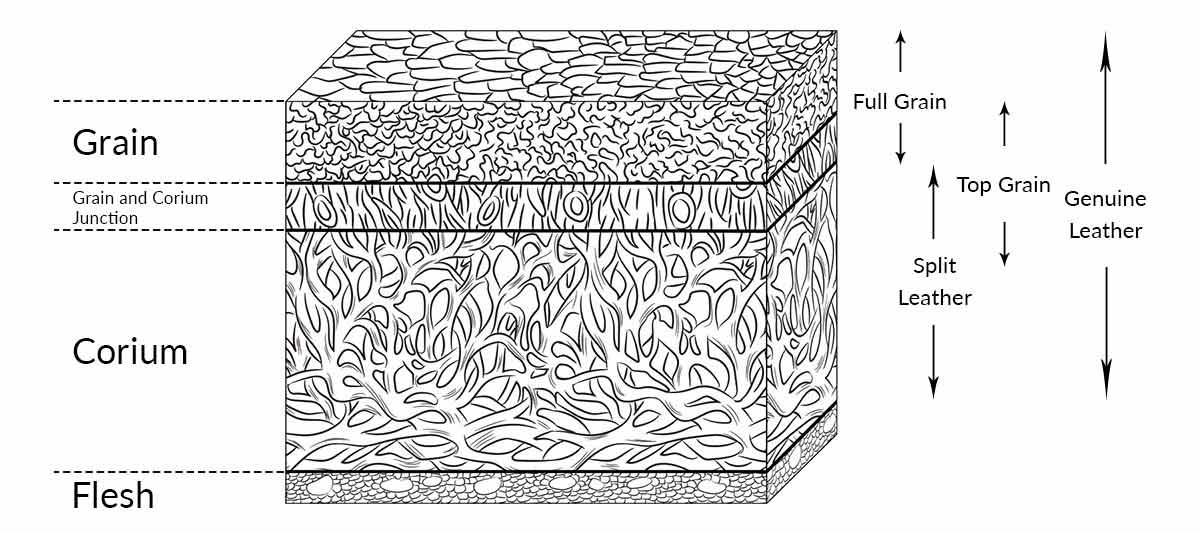

Apart from the construction of a shoe, the other most important aspect is the choice and quality of leather. As with most things in life leather has variations, or “grades”. Here is a quick overview of the most common grades of leather.

Full Grain Leather is the best quality leather sitting at the top of the chain. The majority of our smooth leathers can be categorized as high grade full grain leathers. It refers to the outside part of the animal’s hide just below the hair. The term “Full” means that it has not been buffed or sanded, which is a process that is used to remove imperfections or marks. The tight porous nature of the leather prevents moisture retention but it also means that it is thicker.

Essentially, Top Grain Leather is like full grain but with a twist. It undergoes light sanding to shave off a few millimeters from the top, removing any imperfections. One of the most prominent kinds of top grain leathers is Nubuck.

Lastly, the most common type of leather comes in many forms and has many names but is best known as Split Leather. It is created from the Corium part of the hide after it is split off the grain layer, hence its name. A prominent kind of split leather is Suede.

Our Production Supply Chain

Buying leather may sound easy. Pick up the phone. Place an order. Leather arrives… well, not here.

If we send leather into the factory that is not up to Bespoke Factory standards, the product suffers, the factory struggles and we cannot meet our partner’s expectations. Leather buying (and Clicking) is link number one of the supply chain (in production), and if we allow cut leather sections go that are the wrong color, wrong substance or are sub-par, it will cost BF further down the line.

If leather issues are not flagged up by our Clickers it has a knock on effect throughout the next stages of production – closing, lasting, finishing. And the shoes will not stand up to our Managing Director’s exacting standards.

This is why great importance is placed on searching and buying the most expensive element to our high quality footwear.

The Break of the Leather

When sourcing the higher grade full grain box calf from the best European tanneries, we are always looking for a material that has a ‘fine break’.

There is a saying in the industry –‘the break of the leather’– which refers to creases made as the leather naturally flexes time and time again as it is worn. Of course, all shoes take a huge amount of punishment as they are worn day-to-day, open to the elements.

Only the finest full grain leather, if cared for well, will continue to spring back and hold its shape over time, so we always look for ‘a good clean break’ in our leathers.

Meet the New Box Calf

In case you missed it, we have teamed up with a new Italian tannery, specialized in the production of high grade box calf leather. The tannery dates back more than 100 years ago. It was founded in 1865, and has been dedicated – exclusively – to the tanning of superior quality leather for international top brands.

They work for brands such as Gaziano & Girling, Crockett & Jones or Gucci, to name a few. The most characteristic property of their exceptional Box Calf lies on their calves small size (younger) and thicker skin, which accounts for the uniqueness and quality of the final product. Learn More.

Do not take our word for it. Order a sample!

We really encourage you to get your hands on some box calf samples as soon as possible. You should see the new product in your hands!

Do not have an account yet or your account is inactive? No problem, get in touch with us.